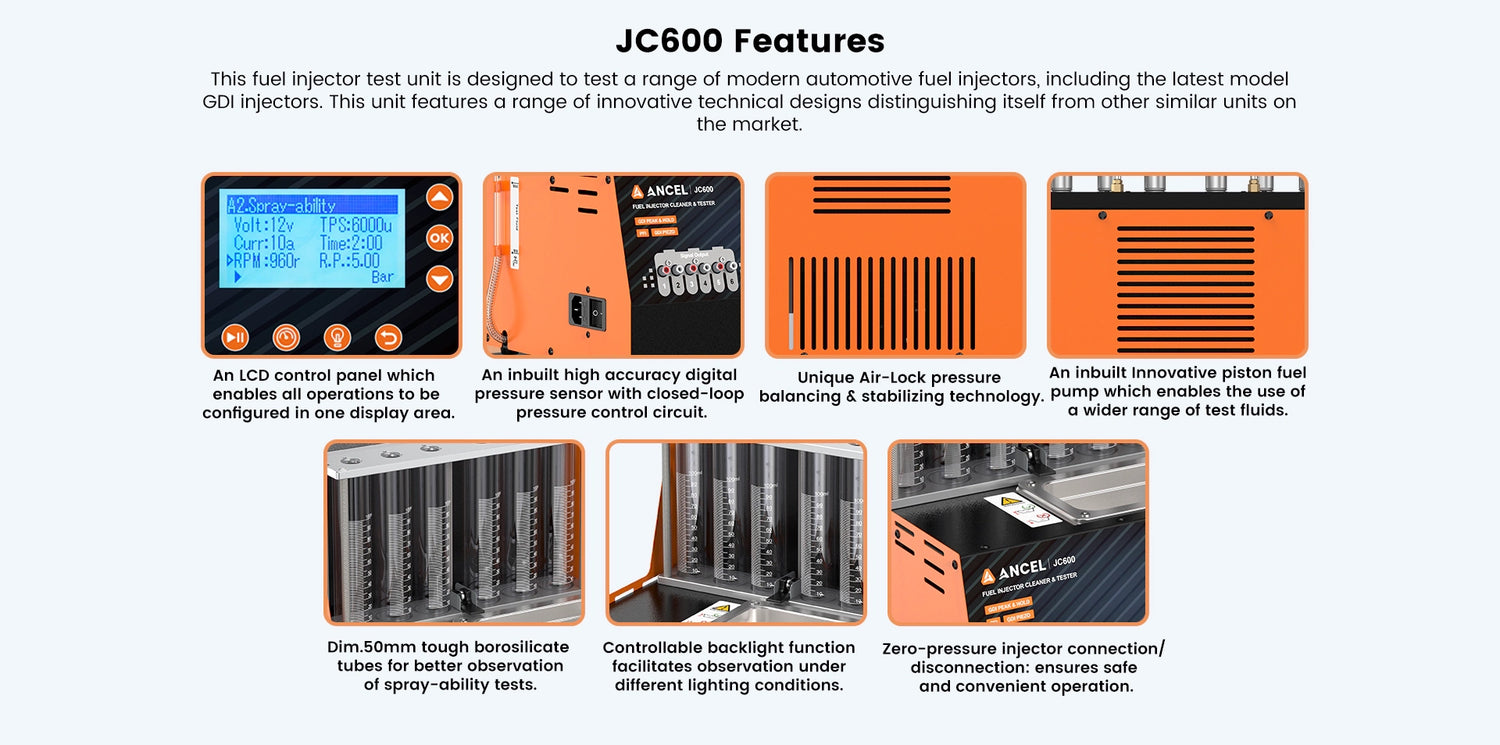

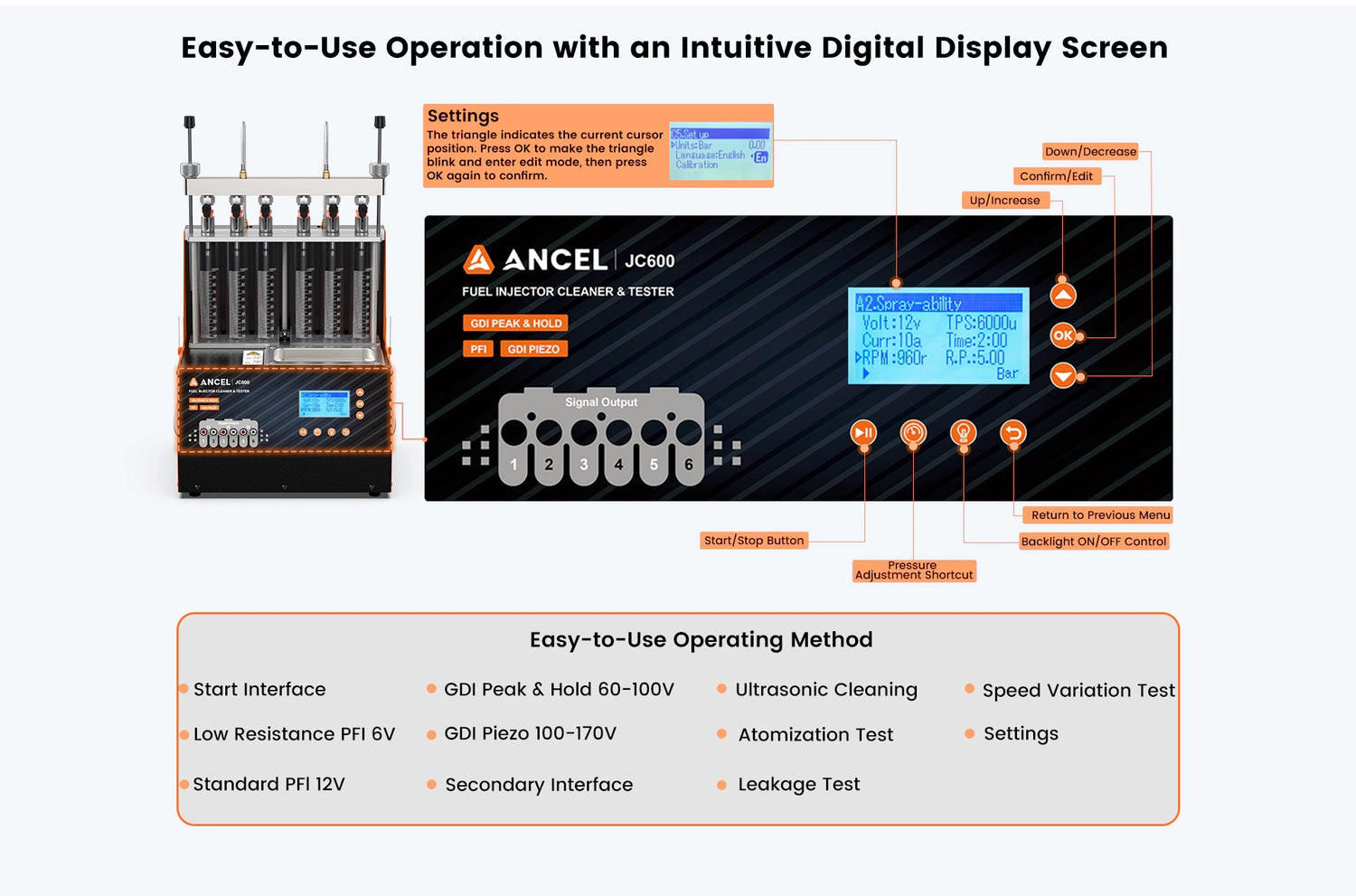

Safeguard Your Engine's Power and Longevity: Master Fuel Injector Care with ANCEL JC600

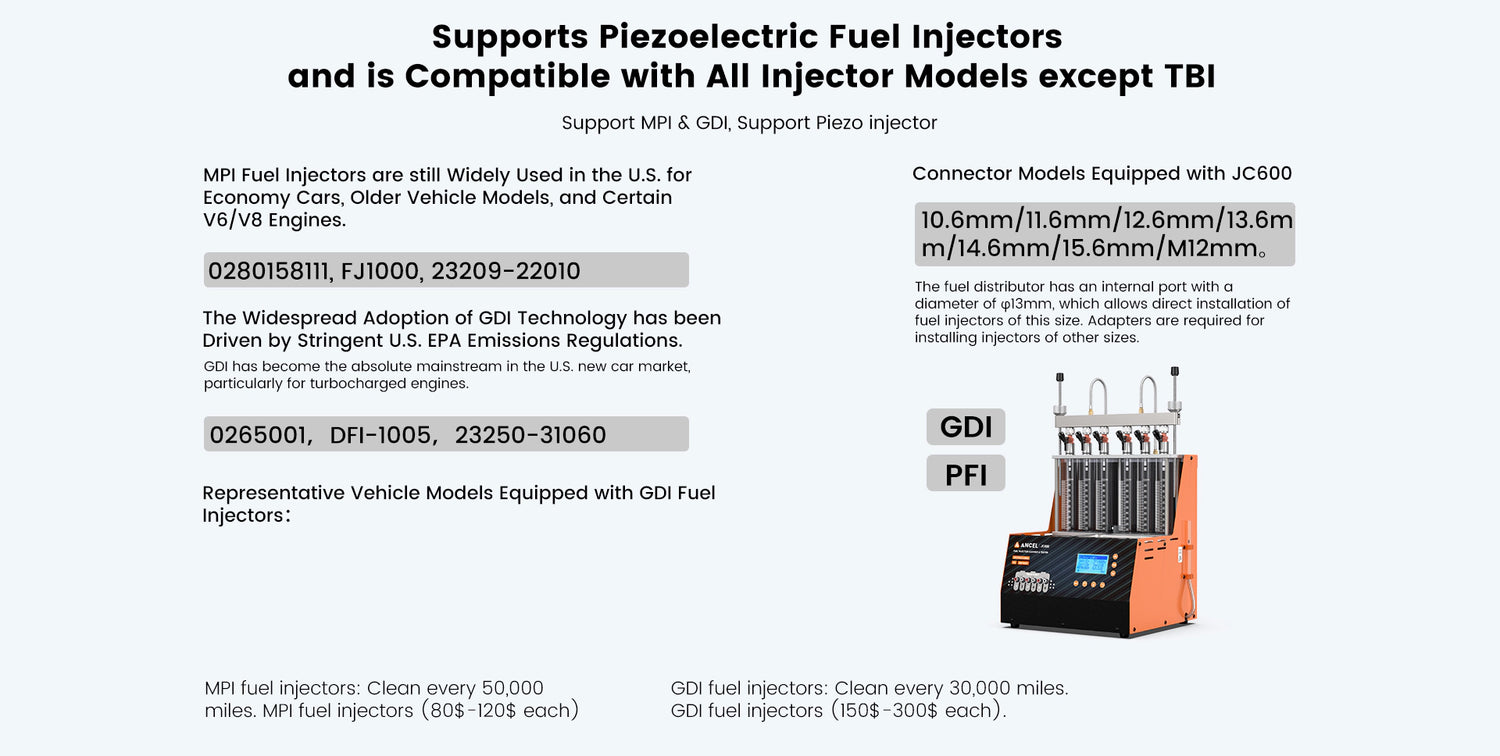

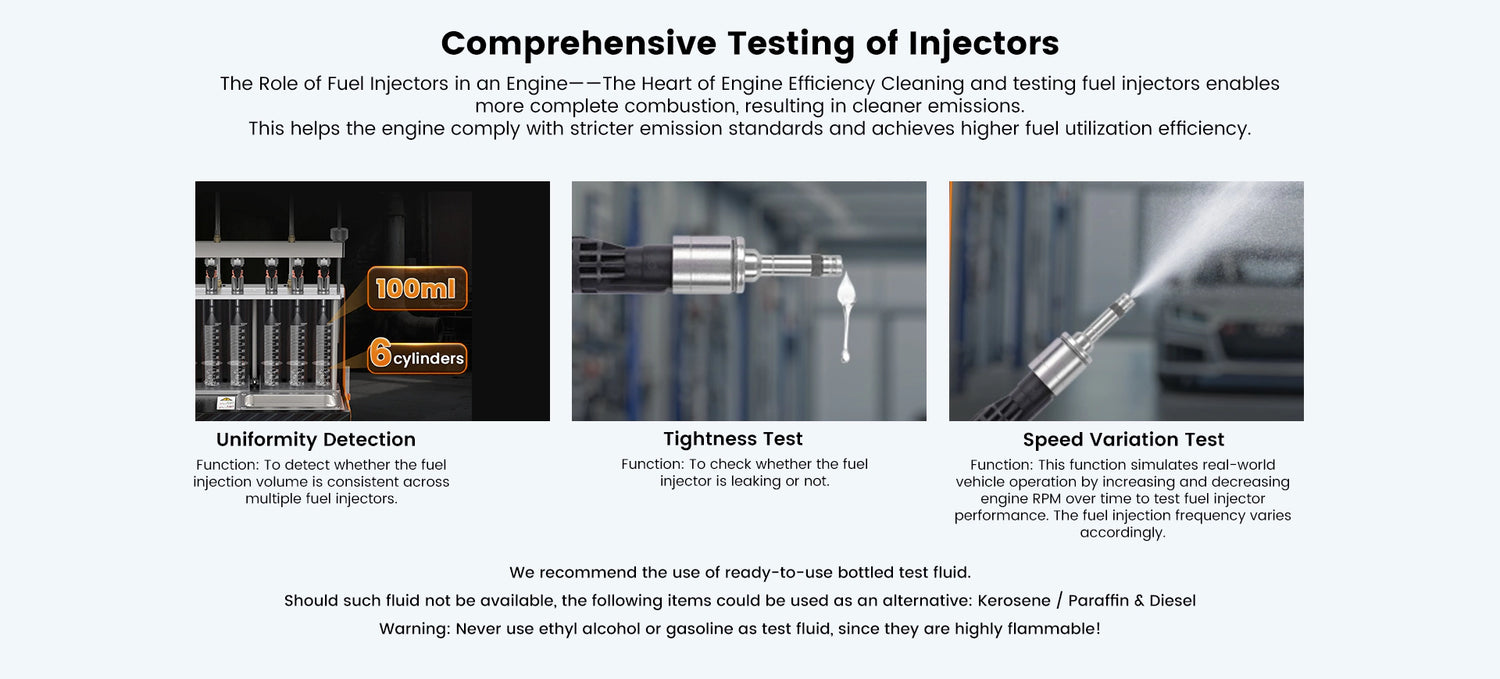

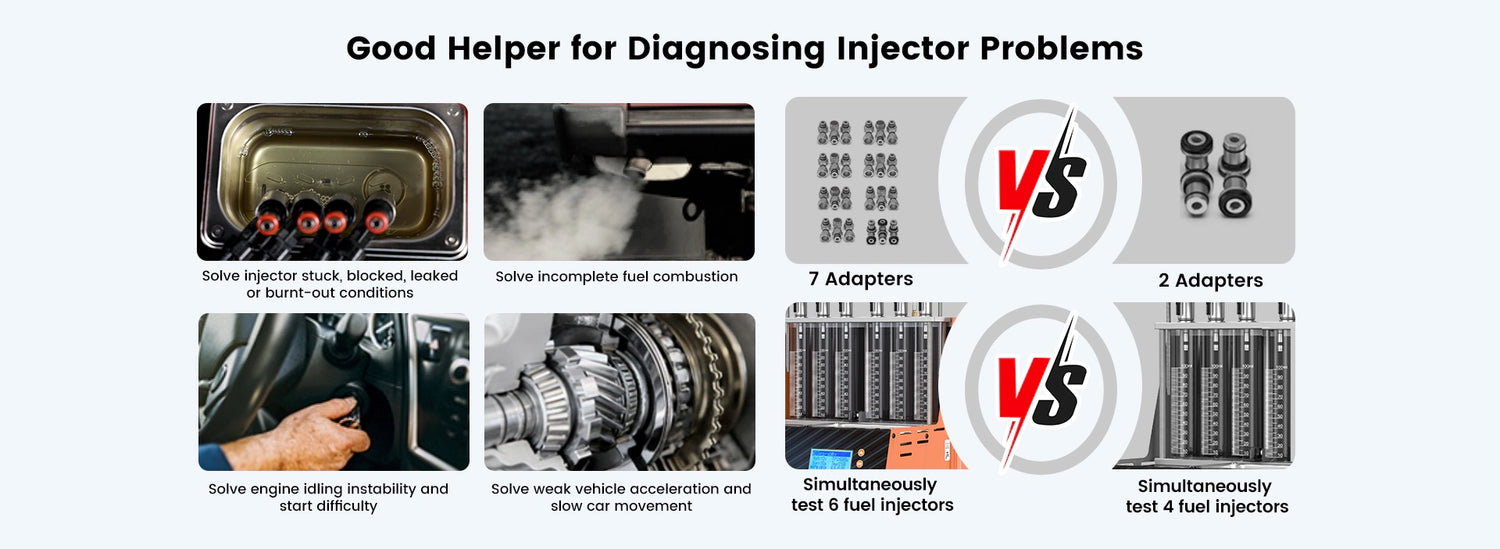

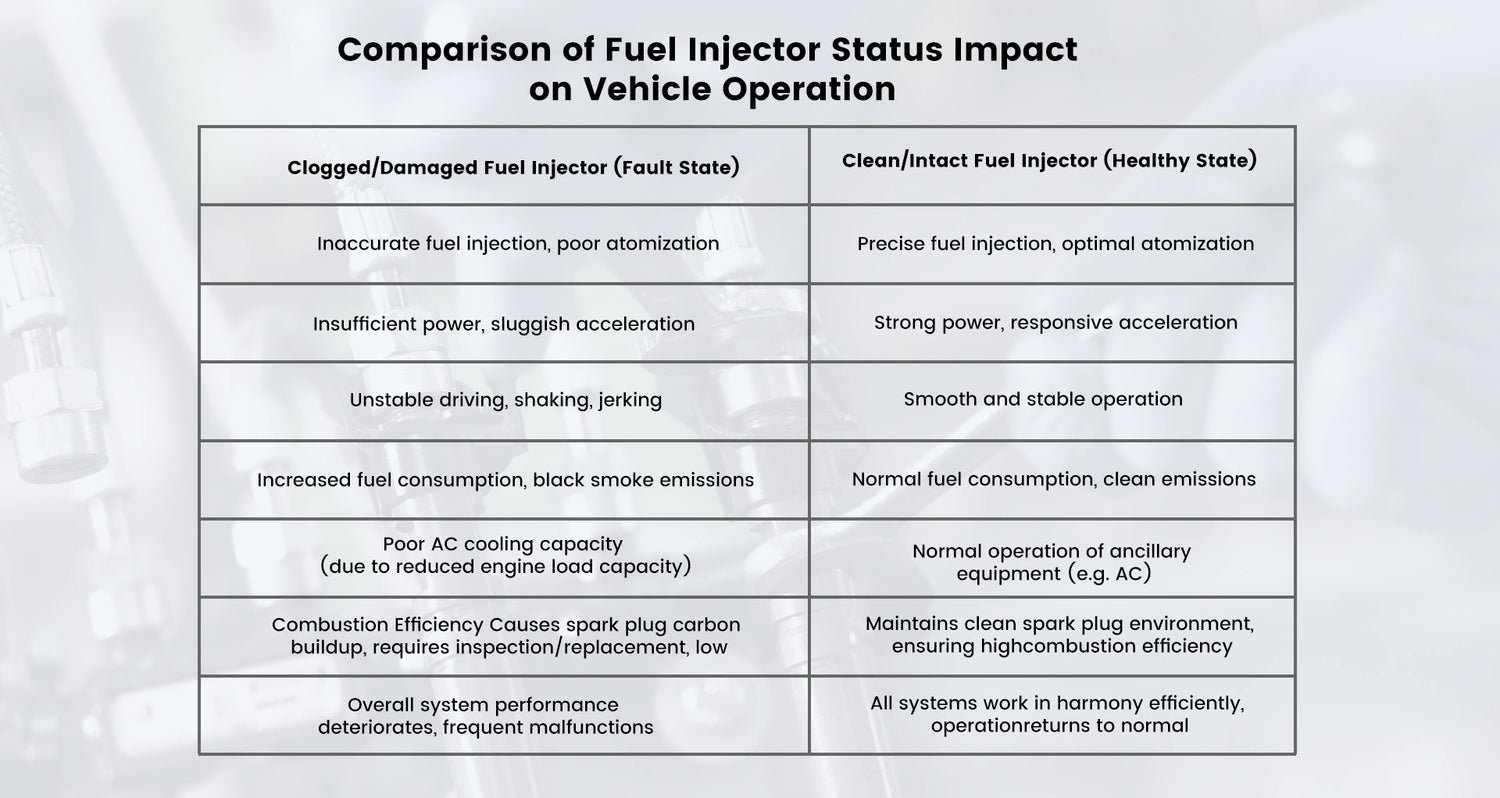

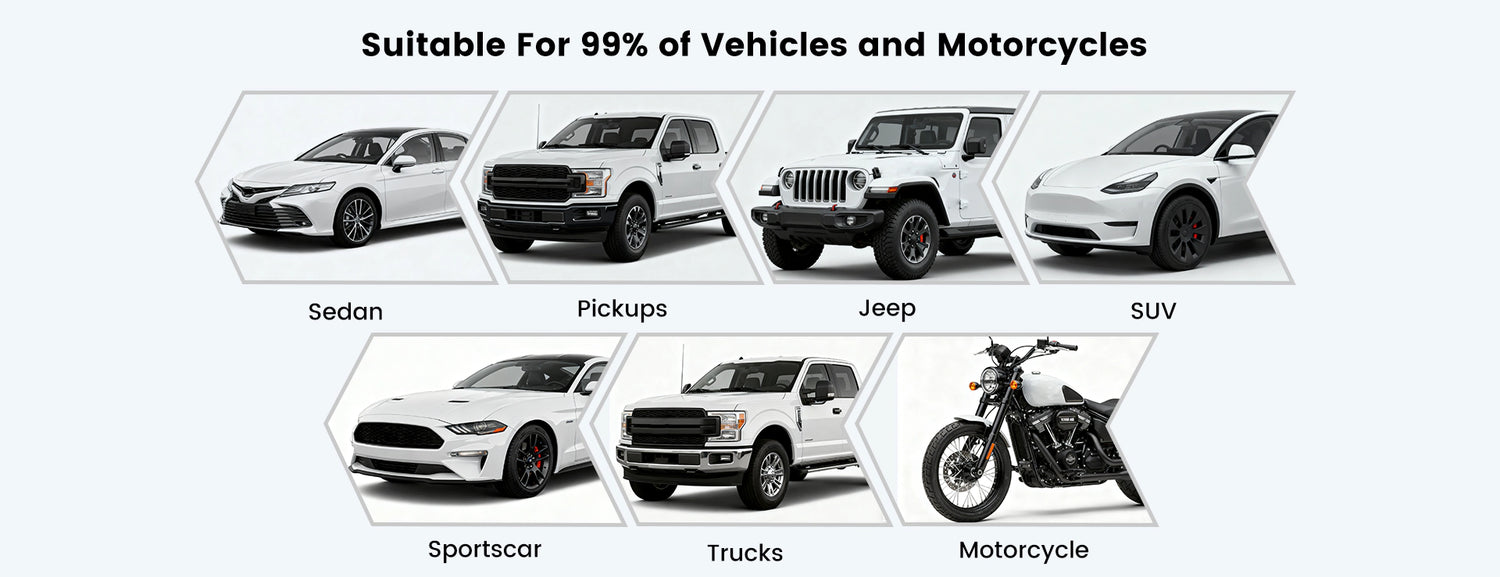

A malfunctioning fuel injector in your car or motorcycle can lead to a significant loss of power. In severe cases, it may even compromise the engine's overall lifespan. Therefore, it is essential to pay close attention to your fuel injectors, identifying and addressing issues early to ensure they do not affect the normal operation of your vehicle.The ANCEL JC600 Fuel Injector Tester and Cleaner is the expert solution for injector-related problems in both cars and motorcycles. Equipped with three specialized functions, it is capable of cleaning and testing a wide range of injector types, including:

- GDI Peak & Hold

- GDI Piezo

- PFI High Resistance

- PFI Low Resistance

It provides robust support for the maintenance and diagnostics of automotive and motorcycle fuel injectors, making it an increasingly popular choice among vehicle owners and auto repair shops alike.

Fuel Injector Cleaning Intervals Based on Mileage:

PFI Injectors (Low & High Resistance):

Recommended Mileage: Approximately 60k - 100k km

GDI Peak & Hold (Solenoid-type Direct Injection):

Recommended Mileage: Approximately 40k - 80k km

GDI Piezo (Piezo-crystal Direct Injection):

Recommended Mileage: Approximately 60k - 100k km

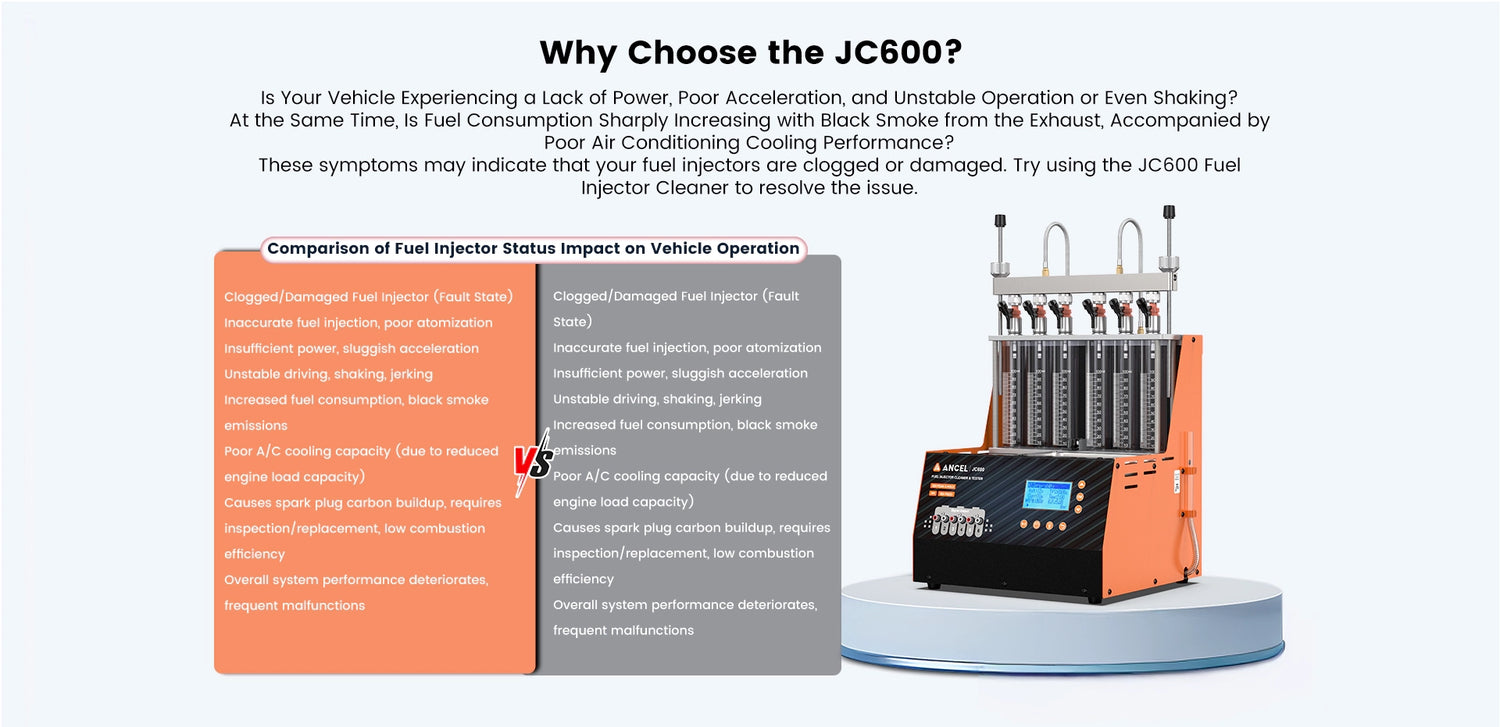

Consider cleaning regardless of mileage if any of the following symptoms occur:

A noticeable increase in fuel consumption

Engine shaking or unstable idling

Poor acceleration or loss of power

Excessive exhaust emissions